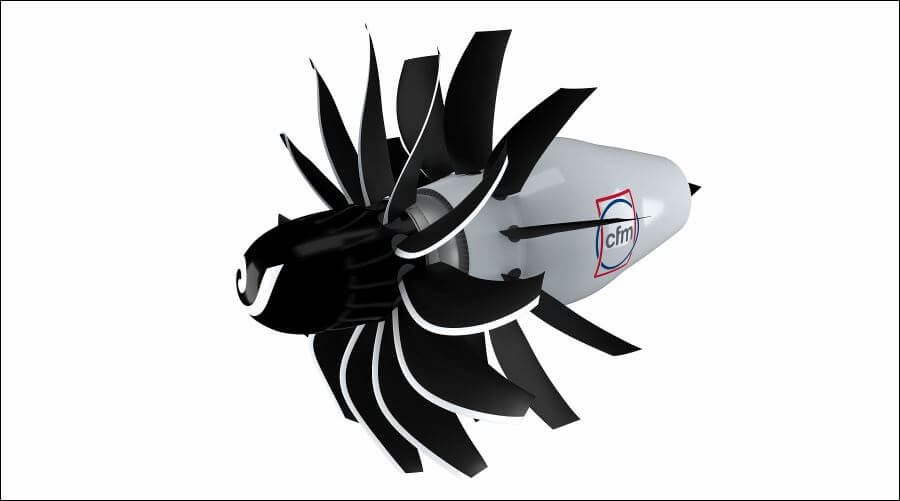

Long-standing engine partners GE Aviation and Safran have launched a new technology demonstration programme called RISE – Revolutionary Innovation for Sustainable Engines – which is aimed at developing open rotor powerplants that can be powered by 100% sustainable aviation fuel or liquid hydrogen for the next generation of single-aisle aircraft from 2035. The two companies have also signed an agreement to extend the CFM International 50/50 partnership, which manufactures the CFM range of LEAP and CFM56 engines, to the year 2050. The RISE programme has a target of developing technologies that will deliver more than 20% greater fuel efficiency and lower CO2 emissions compared with today’s engine generation, reports Mark Pilling. Open rotor engine technology is not new but the potential fuel savings on offer have been offset in the past by an increased noise penalty. However, the partners insist noise levels will be no higher than those from current LEAP engine technology.

“It is a programme to support the future launch of a new CFM engine to succeed LEAP,” said Olivier Andriès, Chief Executive of Safran. “We must act with a burning sense of urgency, and we must rise to the challenge of decarbonisation,” said John Slattery, Chief Executive of GE Aviation, speaking alongside Andriès in Paris on 14 October during the online launch of RISE.

GE and other engine manufacturers, including Safran and Rolls-Royce, have been developing this technology for decades. GE and NASA first began working on open rotor concepts in 1970s in response to an international oil crisis and testing continued in earnest during the 1980s. When the price of oil plummeted in the mid-1990s, the viability of open rotor propulsion came into question, despite the promise of improved fuel efficiency.

However, CFM believes open fan, or open rotor, engine architecture is the game changing technology that will provide the step change to unlock the ambitious emission reduction and efficiency targets the industry is targeting, said Delphine Dijoud, Executive Manager, CFM RISE Programme, at Safran Aircraft Engines.

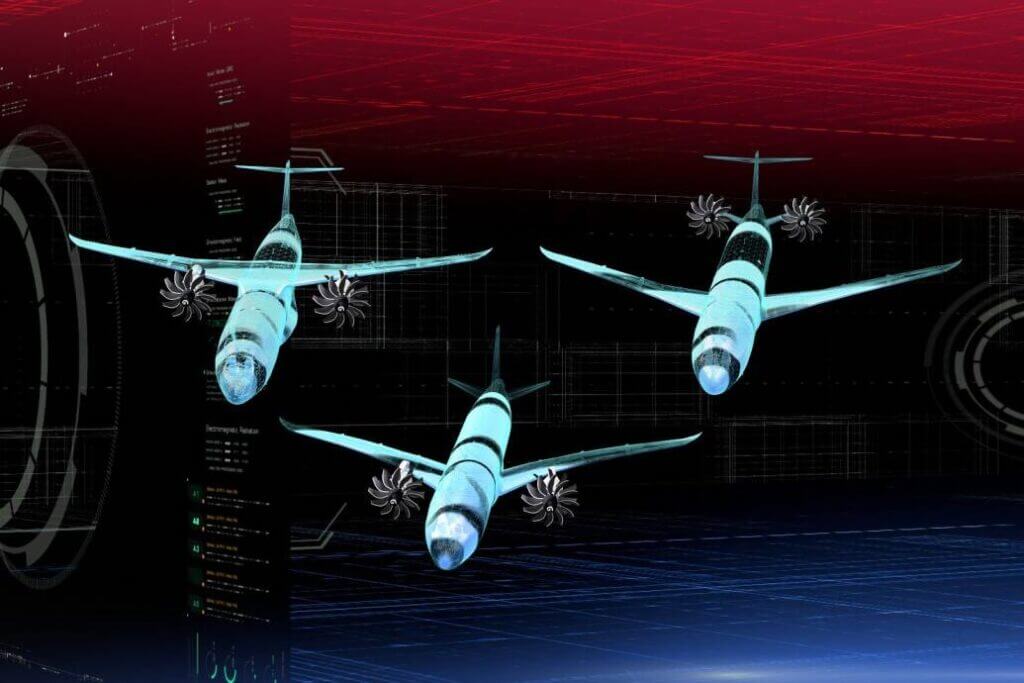

The partners envisage an engine mounted over or under the wing or on either side of the aft fuselage of an aircraft, and the blades not contained within a nacelle, offers significant efficiency gains compared to today’s nacelle-based high bypass ratio fans.

“We have engaged with both Airbus and Boeing on our technology plan,” said GE’s Slattery. The OEMs recognise that open rotor aircraft configurations do offer the reduction levels in emissions and boost in fuel efficiency that will be required, said Andriès, who added: “We have a deep experience of the open fan.”

For travellers, increasingly their “true north” is an awareness of the need to reduce carbon emissions, and a technology that achieves this will be a positive development, suggested Slattery.

On cabin and exterior noise, he said there would be no degradation relative to that experienced from CFM’s latest technology LEAP engine. “That’s our minimum commitment,” he promised.

According to GE Aviation’s Arjan Hegeman, General Manager for advanced technology operation, RISE will focus on three main technology pillars: advanced architecture (open rotor), advanced materials and hybrid electrification of the engine to reach the 20% target. RISE is being led by a joint GE/Safran engineering team that has laid out a technology roadmap including composite fan blades, heat resistant metal alloys, ceramic matrix composites, hybrid electric capability and additive manufacturing. RISE will use hybrid electric capability to optimise engine efficiency while enabling electrification of many aircraft systems.

The partners began collaborating on RISE in 2019 and by the end of this year there will be 1,000 engineers across the two companies working on it, reported Mohamed Ali, VP and General Manager Engineering at GE Aviation. A demonstrator engine is scheduled to begin testing at GE and Safran facilities around the middle of this decade and flight testing soon thereafter, he said.

The use of sustainable aviation fuel will be essential for RISE and it will be designed to run on 100% SAF and be compatible with liquid hydrogen, said Slattery. “Ninety percent of the engine will be the same whatever the fuel [SAF or hydrogen],” explained Andriès. He noted the recent announcement that Airbus, Safran, Dassault Aviation, ONERA and the French Ministry of Transport will launch an in-flight study at the end of 2021 to analyse the compatibility of unblended SAF with single-aisle aircraft and commercial aircraft engine and fuel systems, as well as with helicopter engines. Known as VOLCAN (VOL avec Carburants Alternatifs Nouveaux), this project is the first time that in-flight emissions will be measured using 100% SAF in a single-aisle aircraft.

Both Slattery and Andriès stressed RISE is a technology development programme and not an engine launch. That will come when an OEM launches a new aircraft, they said. Asked about competition from the other engine OEMs, Slattery believes the collective mission of the industry is ultimately to deliver sustainable aviation. “We encourage them to engage now, compete with us, bring their best engines. We welcome their competition – let’s go for it,” he said.

“Our industry is in the midst of the most challenging times we have ever faced,” said Andriès. “We have to act now to accelerate our efforts to reduce our impact on the environment. Since the early 1970s, breakthrough engine efficiency and reliability have been the hallmark of our historic partnership and our LEAP engine already reduces emissions by 15% compared to previous generation engines. Through the extension of our CFM partnership to 2050, we are today reaffirming our commitment to work together as technology leaders to help our industry meet the urgent climate challenges.”

Added Slattery: “Together, through the RISE technology demonstration programme, we are reinventing the future of flight, bringing an advanced suite of revolutionary technologies to market that will take the next generation of single-aisle aircraft to a new level of fuel efficiency and reduced emissions. We fully embrace the sustainability imperative. As we have always done in the past, we will deliver for the future.”

The original framework agreement creating CFM International as a 50/50 joint venture between the two aircraft engine manufacturers was signed in 1974. The partnership was renewed in 2008 for the launch of the LEAP engine programme. More than 35,000 CFM engines have been delivered to more than 600 operators around the globe, accumulating more than one billion flight hours.

Top image: CFM RISE – rendering of concept airframe configuration

Launch of RISE programme:

More News & Features

SITA teams with Arab airlines on developing technology to enhance flight sustainability

Alaska Airlines invests in innovative commercial blended-wing body aircraft developer JetZero

US awards $291 million in grants to accelerate low-emission aviation technologies and SAF production and use

Dovetail gets Australian state support and secures seaplane electric conversion deal from Norway

United Airlines’ venture arm adds eight new partners to its $200m Sustainable Flight Fund

Boeing selects Pratt & Whitney and Collins to support new NASA sustainable flight test programme